Are you tired of bumpy rides and unsightly cracks diminishing the appearance and safety of your property? As a property owner or manager, asphalt problems can be a persistent headache. However, selecting the proper repair method can transform your pavement into a smooth, durable surface. Today, we’ll delve into two prominent options: infrared asphalt repair and traditional patching. We’ll explore their advantages and disadvantages and help you determine which is the best asphalt hole repair for your specific needs.

Understanding Your Options: Infrared vs. Traditional Patching

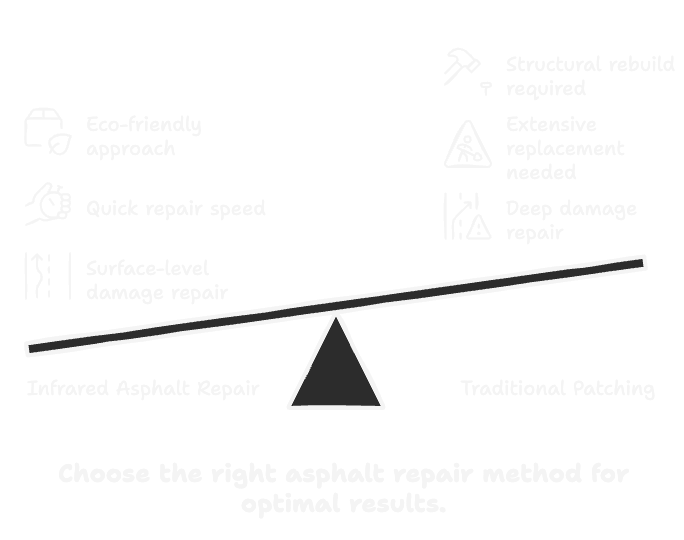

Both infrared asphalt repair and traditional patching aim to fix damaged asphalt, but they employ fundamentally different approaches. Knowing these distinctions is key to deciding how to patch asphalt for your commercial or residential property.

Infrared Asphalt Repair: A Modern, Seamless Approach

Infrared asphalt repair is a cutting-edge technique using infrared heat to soften and blend damaged asphalt with fresh material. This creates a seamless, long-lasting repair that integrates directly with the surrounding pavement.

What are the benefits of infrared asphalt repair?

- Lightning Speed: Repairs can often be completed in as little as 15-30 minutes, minimizing disruption for your business or residents. This quick turnaround is a significant advantage for high-traffic areas.

- Seamless Integration: Unlike traditional methods, infrared repair creates a bond without cold joints or seams. This eliminates the weak points where water typically infiltrates, leading to longer-lasting maintenance and significantly reducing the likelihood of future cracking around the patch.

- Cost-Effective and Eco-Friendly: This method recycles the existing asphalt on-site, dramatically reducing waste and conserving resources. Reusing existing material can also lead to material cost savings.

- Extended Repair Season: Because the infrared heater warms the existing asphalt to temperatures comparable to new hot mix (over 300°F), repairs can be performed in colder temperatures than traditional methods, extending the working season.

- Enhanced Durability: The seamless fusion of old and new asphalt results in a highly durable patch that better resists water damage, freeze-thaw cycles, and heavy traffic loads.

However, there are limitations to consider:

- Surface Level Only: Infrared repair is ideal for surface-level damage, such as potholes, alligator cracking, and minor depressions. It cannot address deep structural issues or damage to the underlying subbase.

- Specialized Equipment & Skills: Operating the specialized infrared equipment requires trained and experienced technicians, which might affect availability and initial project cost compared to tiny traditional patching jobs.

Traditional Patching: The Tried-and-True Method

Traditional patching involves cutting out the damaged section of asphalt, removing the old material, and replacing it with new hot asphalt mix. It has been a reliable method for decades and offers versatility for various types of damage.

Benefits of Traditional Patching:

- Damage Versatility: Traditional patching is highly versatile and can address many issues, including deep potholes, extensive cracking, and areas where the subbase is compromised. It’s often the go-to for more severe structural failures.

- Handles Deeper Issues: Traditional cut-and-fill methods are necessary to ensure a stable and lasting repair when the damage extends beyond the asphalt surface into the base layers.

- Readily Available Tools: This method can be performed with commonly available paving equipment, potentially reducing contractors’ initial equipment investment.

Trade-offs to consider:

- Longer Repair Times: Cutting, excavating, and replacing asphalt is more time-consuming, potentially causing greater inconvenience and disruption to traffic or property access.

- Shorter Lifespan (Potentially): The primary drawback is the creation of “cold joints” or seams between the old and new asphalt. These seams are susceptible to water infiltration and can be prone to cracking over time, leading to a shorter lifespan than seamless infrared repairs.

- Environmental Impact: This method typically involves more new material consumption and disposal of old asphalt, contributing more to waste and resource depletion.

So, which method is the most suitable for your asphalt repair?

The ultimate choice between infrared asphalt repair and traditional patching depends on your pavement damage’s specific nature and extent, budget, and environmental considerations.

- Choose Infrared Asphalt Repair for:

- Surface-level damage like potholes, small areas of alligator cracking, and utility cuts.

- When quick repairs and minimal disruption are paramount.

- This is for long-term durability and a seamless finish that prevents water intrusion.

- If environmental concerns and recycling existing materials are a priority.

- To understand the benefits of infrared asphalt repair, remember its efficiency, durability, and eco-friendliness for appropriate applications.

- Opt for Traditional Patching for:

- Deep damage that extends into the subbase.

- Extensive areas of asphalt failure require a complete removal and replacement.

- When the flexibility to address diverse damage types is the primary concern.

- In situations where the underlying structure needs to be rebuilt.

Can I put new asphalt over old asphalt?

New asphalt can be placed over old asphalt, often called an overlay. However, this is typically done for larger pavement areas that are generally in good condition but show signs of wear and tear, rather than for isolated patches. For individual potholes or cracks, the methods discussed above are more appropriate. Infrared repair, in particular, effectively blends new material with existing asphalt to create a strong, localized patch without simply “putting new asphalt over old asphalt” superficially. For larger areas, an overlay can significantly extend the life of a pavement, provided the existing subbase is stable and drainage issues are addressed.

Pave the Way to a Smooth Future

Regardless of your chosen method, consulting a reputable pavement professional like American Pavement Solutions is always recommended for a tailored assessment and solution. With the correct information and expert guidance, you can ensure your asphalt surfaces are smooth, safe, and built to last.

American Pavement Solutions is dedicated to providing effective and efficient asphalt repair services. Contact us today for a free estimate and let our experts help you determine the best approach for your asphalt repair needs.